Multi-layer three-dimensional vibratory separator is a high-precision screening and grading machine. With 1-3 screens simply installed, the machine can classify 4 different groups of granular size at the same time. Characterized by high efficiency, high precision, continuity in production, optimized process, etc., the machine is applicable to screen and filter different form materials like powder, particles, slurry fluids,viscosity,etc for all kinds of industries.

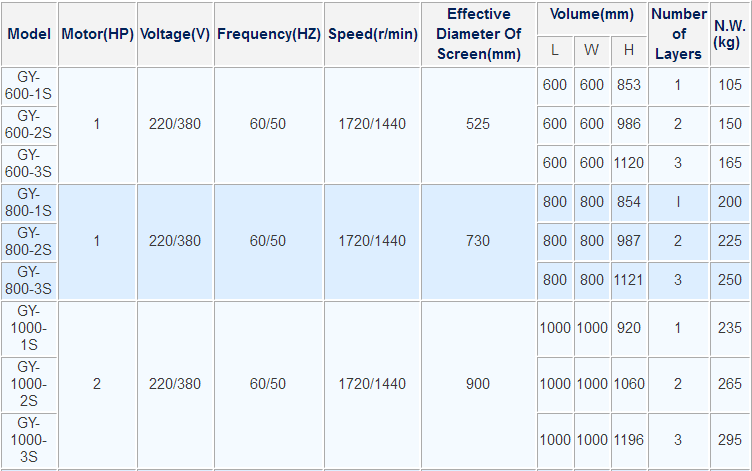

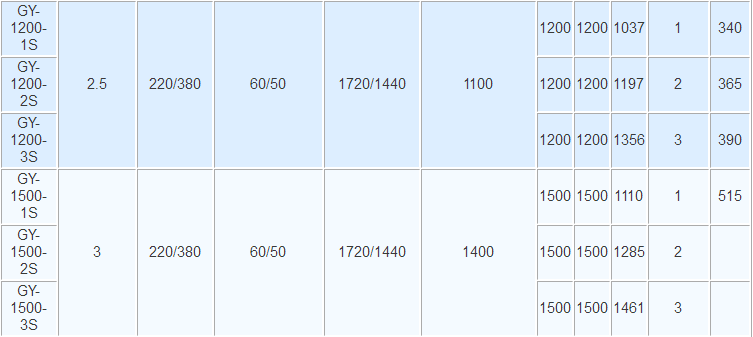

Specifications and Dimension

(Capacity is estimated based on applying mesh#60 for flour powder, it may vary from types, shapes, grains, gravity, temperature, humidity, mesh and other factors.)

Features

The circular separator is capable of sieving a variety lf different size of materials at one time and greatly improve productivity.The eccentric arms angle can be adjusted to improve rotating speed and amplitude to reach much higher sieving efficiency.The extra devices like jumping balls, nylon brush, and Teflon rings also help to enhance the screening performance.

Rational and optimized design and advanced manufacturing process improve the machine service life. Operation is safe and reliable with low noise.

Patented unique screen structure is convenient and easy to install or change mesh which only takes 3-5 minutes, simple to operate and easy to clean.

The mesh can be self-cleaned, no powder fly, discharge speedily, high efficiency and the finest mesh size is up to 400mesh or even finer.

Small size, light weight, easy to move; discharge outlet position can be adjusted and identify big and small size be separated automatically and precisely.

Simple maintenance, can be assembled as a single layer or multiple layers.

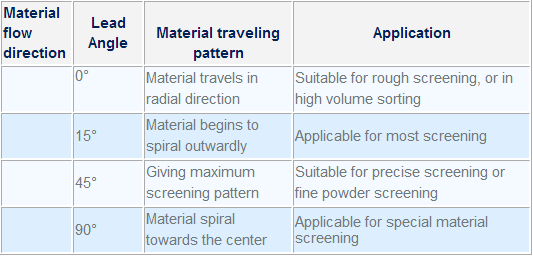

Principle